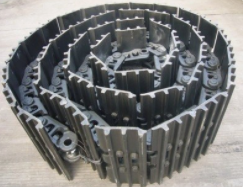

Nxiba umthetho wezihlangu zomzila

Ngexesha lokusebenza okuqhelekileyo, ipini yengoma ijikeleza kancinane ngasemva kumngxunya wephini, ezi zimbini zinxiba ngokulinganayo, umngxunya wephini ngokuthe ngcembe uya uba mkhulu, kwaye isikhonkwane sincipha kancinci kancinci.Ukuba umsebenzi awufanelekanga, njengokujika kwesantya esiphezulu, ukuqalisa ngequbuliso, okanye ukungena emanzini anodaka, ukhula, njl.njl. ukuvala izikhonkwane, kuya kubangela ukuba amacala asekhohlo nasekunene kwizihlangu zomzila acinezeleke kakhulu kwaye axeke, izikhonkwane ziya kuba gwenxa kwaye zigobe.Ukujikeleziswa, isikhonkwane kunye nomngxuma we-pin iba yi-sliding friction, kwaye inxalenye ye-friction ilinganiselwe kwindawo encinci yokudibanisa, i-pin iculwa ngokuthe ngcembe ibe yi-crank shape, kwaye umngxuma we-pin nawo uba yi-ellipse.

Ukonyuka komngxunya we-pin kwakhona kubangela ukuba i-pitch yomzila ibe nde (i-pitch yimgama osembindini wemingxuma kuzo zombini iziphelo zesihlangu somzila), ngoko isihlangu somzila kunye nevili lokuqhuba ziyasila enye kwenye, isihlangu somzila sigugile. , kwaye amazinyo evili lokuqhuba amile okwencakuba.Ngokomlinganiselo, xa i-pitch iguqulwa ukusuka kwi-174 mm ukuya kwi-184 mm, ububanzi bokuvula amazinyo okuqhuba amazinyo atshintshile ukusuka kwi-87 mm ukuya kwi-97 mm, kwaye i-meshing eqhelekileyo ichithwa ngokupheleleyo ngeli xesha.

Kuba i-pitch yezihlangu zomkhondo inde, ibangela ukuba iirola zitsibe ngexesha lokuhamba, nto leyo ekhawulezisa ukunxiba komgaqo wesihlangu somzila.Xa i-subsidence yomgaqo weenqwelo-moya inkulu kune-4 mm, kufuneka ilungiswe.

Ukunxitywa kwenxalenye yesikhokelo yesihlangu somzila kubangelwa ikakhulu ukuphambuka komzila, ukuguqulwa okunzima kwesicathulo somzila, kunye ne-axial shaking egqithisileyo ye-roller kunye nevili lesikhokelo.

Izihlangu eziqhelekileyo ezilahliweyo zinxitywe kakhulu okanye zinxitywe kwi-meshing part kunye nevili lokuqhuba.

Ukulungiswa kwezihlangu zomzila

Ukunxitywa kwesihlangu somzila ubukhulu becala kunamacandelo amabini: umphezulu wendlela yomdyarho kunye nomngxuma wephini lomkhondo.Kulula kakhulu ukuyilungisa.Emva kokuba i-raceway igugile, i-groove iyancipha, kwaye xa ubunzulu bungekho ngaphezu kwe-2 ~ 3 mm, inokubonakala ngokuthe ngqo kwaye ilungiswe.Xa ukunxiba kunzulu, imivalo yensimbi yobukhulu obuhlukeneyo inokuzaliswa kwiigrooves ngokwemiqathango ethile, kwaye emva koko i-welded ukusuka kumacala onke.Umngxuma wephini kufuneka ubuyiselwe kubungakanani bokuqala kunye nendawo ephakathi yomngxuma wokuqala emva kokusila.Ngenxa yale njongo, sika umngxuma we-pin ogugileyo, ufake iphini yobungakanani obuqhelekileyo, emva koko uyifudumeze malunga ne-800 ℃, kwaye emva koko usonge umda wendlebe.Yongeza ipleyiti yentsimbi enesiqingatha sesetyhula ukuya ngaphandle kwe-incision kwaye uyidibanise ngokuqinileyo nge-welding yombane.Izihlangu zomzila zilungiswa ngolo hlobo zinokuhlala ngaphezulu kweeshifti ze-100.

Indawo yentsimbi yezihlangu zomkhondo

Izihlangu zomkhondo wezithuthi ezilandelwayo ngokubanzi zenziwe ngentsimbi ephezulu yemanganese enembali emalunga nekhulu leminyaka yokusetyenziswa.Oku kungenxa yokuba intsimbi ephezulu yemanganese inophawu olubalaseleyo, oko kukuthi, ifumana ukuqina kwempembelelo phantsi kwesenzo somthwalo wempembelelo, iyenze ibe kumgangatho ongaphezulu oqinileyo kwaye ungagugi, ngelixa ugcina ukuqina kunye neplastikhi yayo yangaphakathi. umaleko.Nangona kunjalo, intsimbi ephezulu ye-manganese isetyenziswa njengesihlangu somzila, esihlala sonakaliswa kwangoko ngenxa yokuqhekeka, amazinyo aguquguqukayo kunye nokuphambuka ngexesha lokusetyenziswa, kwaye unobomi obuphantsi benkonzo.Ukuze unqobe le ntsilelo, i-alloy low-alloy high-strength steel 30SiMnMoV (Ti) insimbi, esekelwe kwimithombo yasekhaya kwaye kulula ukuyivelisa, iphuhlisiwe.Isetyenziswe ngempumelelo ukutshintsha intsimbi ye-manganese ephezulu ukwenza izihlangu zomkhondo.

iindlela zokulungisa

Itekhnoloji yokucubungula isicathulo somkhondo weprofayili ngokuqhelekileyo: ukusetyenziswa kweprofayili yokusika, ukugaya (ukubetha), unyango lobushushu, ukulungiswa, ukupeyinta kunye nezinye iinkqubo;umkhondo we-bulldozer uqiniswa-nye, kunye nombala wepeyinti jikelele utyheli;Ineembambo ezintathu, kwaye umbala wepeyinti umnyama.Izinto ezithengiweyo zeprofayili ngokuqhelekileyo ziyi-25MnB, kwaye ubulukhuni bokugqibela bokulungiswa kobushushu bezinto eziphathekayo yi-HB364 ~ 444.

Ixesha lokuposa: Aug-26-2022