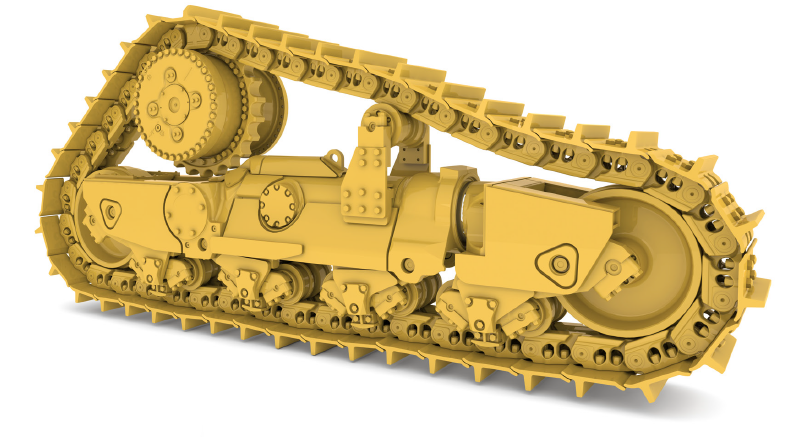

Iindlela zokusombulula iingxaki zolondolozo lwemihla ngemihla lwe-bulldozer undercarriage

(1) Ingoma yesikhasi igcina uxinzelelo olululo

Ukuba uxinzelelo luphezulu kakhulu, uxinzelelo lwasentwasahlobo lwe-pulley engasebenziyo lusebenza kwiphini lomkhondo kunye ne-track bushing, isangqa sangaphandle sepini kunye nesangqa sangaphakathi somkhondo bushing siphantsi koxinzelelo oluphezulu lwe-extrusion, kunye nepini kunye i-track bushing iya kunxitywa ngaphambi kwexesha ngexesha lokusebenza.Amandla e-elastic entwasahlobo nawo asebenza kwi-idler shaft kunye ne-bushing, ekhokelela kuxinzelelo olukhulu lonxibelelwano lomphezulu, olwenza ukuba i-idler bushing igaye ibe lula kwi-semicircle, kwaye i-pitch ye-track pitch ilula ngokulula, kwaye iya kunciphisa oomatshini. ukuhambisa kakuhle kunye nokuchitha ukuhanjiswa kwe-injini kwi-sprocket kunye namandla okulandelela.

Ukuba i-tension yengoma ikhululekile kakhulu, ingoma iya kwahlulwa ngokulula kwi-idler kunye ne-roller, kwaye ingoma iya kuphulukana nokulungelelaniswa kwayo okuchanekileyo, okuya kubangela ukuba umzila obalekayo uguquguquke, ubethwe, kwaye ube nempembelelo, okukhokelela ekunxityweni okungaqhelekanga kovila. kunye nerola.

Ukulungelelaniswa koxinzelelo lwe-crawler lwenziwa ngokufaka ibhotela kwi-oyile yokuzalisa i-nozzle ye-cylinder ye-tension okanye ukukhulula ibhotela kwi-oil discharge nozzle, kunye nokulungelelanisa ngokubhekisele kwi-standard clearance yemodeli nganye.Xa i-pitch yamacandelo engoma isoluliwe ukuya kwindawo apho iseti yamacandelo engoma kufuneka isuswe, umphezulu we-meshing we-drive wheel tooth surface kunye ne-track bushing nayo iya kunxitywa ngokungaqhelekanga.Umkhono uphendulwe, izikhonkwane ezigugile ngokugqithisileyo kunye ne-track bushings zitshintshwa, kwaye indibano edibeneyo yomzila ithathelwa indawo.

(2) Gcina iongenamsebenziindawo elungelelanisiweyo

Ukungalungelelani kakuhle kwe-idler kunempembelelo enkulu kwezinye iindawo zendlela yokuhamba, ngoko ke ukulungelelanisa isithuba phakathi kwepleyiti yesalathiso sokungenzi nto kunye nesakhelo somzila (ukulungisa ukungahambi kakuhle) ngundoqo wokwandisa ubomi bendlela yokuhamba.Xa uhlengahlengisa, sebenzisa i-gasket phakathi kwepleyiti yesikhokelo kunye nokuthwala ukulungisa.Ukuba i-gap inkulu, susa i-gasket;ukuba i-gap incinci, yandisa i-gasket.Ukukhutshwa okusemgangathweni ngu-0.5 ukuya kwi-1.0mm, kwaye ubuninzi obuvumelekileyo obuvumelekileyo yi-3.0mm.

(3) Guqula iphini lomkhondo kunyeukulandelela bushingngexesha elifanelekileyo

Ngexesha lenkqubo yokunxiba yepini yomzila kunye ne-track bushing, i-pitch yethrekhi iye yandiswa ngokuthe ngcembe, okukhokelela ekuzibandakanyeni kakubi phakathi kwevili lokuqhuba kunye ne-track bushing, ekhokelela kumonakalo we-track bushing kunye nokunxiba okungaqhelekanga kumphezulu wezinyo lokuqhuba. Ivili, eliya kubangela ukujikeleza, ukuqhwaba, kunye nefuthe.Bufutshane kakhulu ubomi bendlela yokuhamba.Xa i-pitch ingenakuphinda ibuyiswe ngokuhlenga-hlengisa ukucinezeleka, kuyafuneka ukuba ujike ipini yengoma kwaye ulandelele i-bushing ukuze ufumane i-pitch echanekileyo.Kukho iindlela ezimbini zokumisela ixesha xa i-pin yengoma kunye ne-track bushing zijika;enye indlela kukumisela ixesha apho i-pitch ye-track yandiswa nge-3mm;enye indlela kukumisela ixesha xa ububanzi yangaphandle umkhondo bushing inxitywe 3mm.

(4) Qinisa iibholithi namandongomane ngexesha

Xa iibholiti zendlela yokuhamba zikhululekile, ziphuka ngokulula okanye zilahlekile, zibangela uthotho lweentsilelo.Ezi bholiti zilandelayo kufuneka zitshekiselwe ukugcinwa kwemihla ngemihla: iibholiti ezikhwelayo zerola exhasayo kunye nerola exhasayo, iibholiti ezikhwelayo zebhlokhi yezinyo levili lokuqhuba, iibholiti ezikhwelayo zesihlangu somzila, iibholiti ezikhwelayo zeplate yonogada, kunye iibholiti ezikhwelayo zentloko yebrace diagonal.Jonga kwincwadana yemiyalelo yemodeli nganye yokuqinisa itorque yeebholithi eziphambili.

(5) Ukuthambisa kwangexesha

I-lubrication yendlela yokuhamba ibaluleke kakhulu.Iibheringi ezininzi ze-roller "zitshiswe zafa" kwaye umrhumo awufumaneki ngenxa yokuvuza kweoli.Ngokuqhelekileyo kukholelwa ukuba ezi ndawo zilandelayo ze-5 zinokuvuza ioli: ngenxa ye-O-ring ehluphekileyo okanye eyonakalisiweyo phakathi kwendandatho yokugcina kunye ne-shaft, ukuvuza kweoli ukusuka kwicala langaphandle lendandatho yokugcina kunye ne-shaft;ngenxa yokungaqhagamshelwa kakuhle kweringi yetywina edadayo okanye isiphene se-O-ring, iOyile ivuza phakathi kwecala elingaphandle leringi kunye neerola (iiroli ezixhasayo, iirola ezikhokelayo, iivili zokuqhuba);ngenxa ye-O-ring embi phakathi kwee-roller (ii-roller ezixhasayo, ii-roller ezikhokelayo, iivili zokuqhuba) kunye ne-bushing, ukusuka kwi-bushing kunye nokuvuza kwe-Oli phakathi kwee-roller;ukuvuza kweoli kwiplagi yokuzalisa ngenxa yeplagi yokuzalisa ekhululekile okanye umonakalo kwimbobo yokuhlala evalwe yiplagi ye-conical;ukuvuza kweoli phakathi kwesigubungelo kunye ne-roller ngenxa ye-O-rings engalunganga.Ke ngoko, kufuneka ubeke ingqalelo ekujongeni la macandelo angentla ngamaxesha aqhelekileyo, kwaye wongeze kwaye uwatshintshe rhoqo ngokuhambelana nomjikelo wokuthambisa wenxalenye nganye.

(6) Khangela iintanda

Ukuqhekeka kwenkqubo ye-undercarriage kufuneka kuhlolwe ngexesha, kwaye ukulungiswa kwe-welding kunye nokuqiniswa kufuneka kuqhutywe ngexesha.

Ixesha lokuposa: Jun-05-2022