Mhayi shaft :Mi-aterial yi-50Mn ephezulu ye-carbon structural steel, enomxholo we-C ukusuka kwi-0.48 ukuya kwi-0.56%, umxholo we-Si ukusuka kwi-0.17 ukuya kwi-0.37%, umxholo we-Mn ukusuka kwi-0.7 ukuya kwi-1.0%, umxholo we-S ukusuka ngaphantsi kwe-0.035%, umxholo we-P ukusuka ngaphantsi kwe-0.035%, kunye nomxholo we-Cr ukusuka ngaphantsi kwe-0.25 ukuya kwi-0.30%, umxholo we-Ni osuka ngaphantsi kwe-0.30%, kunye nomxholo we-Cu ovela ngaphantsi kwe-0.25%. inokuphucula i-ductility kunye neplastiki yezinto eziphathekayo, iqinisekise ukuqina okwaneleyo kunye nokuxhatshazwa kokugqoka.Emva konyango lobushushu, i-50Mn yentsimbi inamandla amakhulu kunye nokuqina, ukungena okugqwesileyo, umaleko wokuqina onzulu, kunye nokuthungwa okuhle kwepearlite, kunye nokusebenza kakuhle koomatshini.

Imigangatho yokuyila i-shaft ephambili ifuna ubunzulu be-2 ukuya kwi-7 mm yomaleko olukhuni kunye nobunzima obuqinileyo be-50 ukuya kwi-62 HRC.

Umzimba :Ukuze kuphuculwe ukumelana nokunxiba kwetrack roller's umzimba, izinto 40Mn2 i-alloy yensimbi yesakhiwo, kunye nomxholo we-C ukusuka kwi-0.37 ukuya kwi-0.44%, umxholo we-Si ukusuka kwi-0.17 ukuya kwi-0.37%, umxholo we-Mn ukusuka kwi-1.4 ukuya kwi-1.8%, umxholo we-P ukusuka ngaphantsi kwe-0.030%, kunye nomxholo we-S. ukusuka ngaphantsi kwe-0.030%.

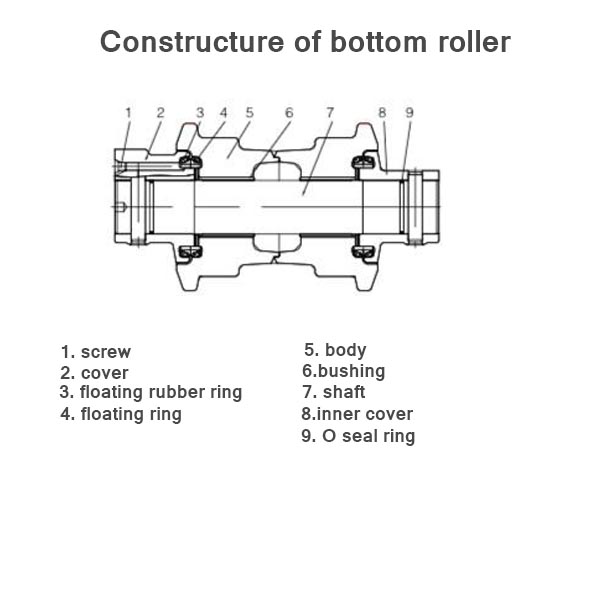

I umqengqelezi ongezantsiumzimba uqulunqwe ngenkqubo yokubumba.Emva kokubunjwa, umzimba wesondo ojikelezayo ugxininiswe ukufezekisa ubunzima be-26-32HRC ukugcina amandla aphezulu, iplastiki, ukuqina, kunye nokusebenza komatshini jikelele ngaphakathi komzimba wevili.Umphezulu womzimba wevili uxhomekeke kunyango lokucima ukunyusa ukuqina kunye nokunxiba ukuxhathisa umzila wevili lenkxaso.Ubunzima bokucima yi-50-58HRC, kunye nobunzulu be-6-12mm.Oku kubangela ukufana okusisiseko phakathi kobunzima bomphezulu kaloliwe kunye nekhonkco lekhonkco elidibeneyo (48-58HRC).

Itywina:Ubungakanani kunye noburhabaxa bomphezulu weO-ringkufuneka ihambelane neemfuno zoyilo.Umphezulu wokukhwelana kufuneka ujikelezwe, kwaye kufuneka kucocwe naziphi na ii-burrs kunye neencam ezibukhali.

Irabha yetywina edadayo kunye ne-O-umsesanekufuneka ikhethwe kwirubha ye-butyl ekumgangatho ophezulu.Ububanzi bangaphakathi, ubungakanani bentambo, ukuqina, ukuqina (unxweme), kunye nokugqitywa komphezulu kufuneka kuhambelane nemigangatho.Ngaphambi kokuhlanganisana, zonke ezi zinto zingasentla kufuneka zihlolwe kwaye zifaneleke ngokuhambelana nemigangatho engentla phambi kokufakwa.

Umsantsa :Ucoceko phakathi kwe-asi engundoqo ye-asi kunye ne-hub ephethe kwi-irolaumzimba kufuneka ube ngu-0.2-0.4 mm.Xa ujikeleza, akufanele kubekho ukuthintelaingxakikunye nokusebenza kakuhle kokutywina, akukho kuvuza kweoli.

Ukuthambisa :Ioli yokuthwala kwiumqulu womkhondor kufuneka ifakwe i-oil pump.Xa kuyimfuneko, i-viscosity yeoli yokuthambisa inokunyuswa ngokufanelekileyo.Ngaphambi kokutofa ioli yokuthwala, i-lubricant ephelelwe lixesha kufuneka ikhutshwe.Emva koko, i-lubricant entsha kufuneka yongezwe kumngxuma weplagi yeoli de i-oyile iphume.Xa ufaka i-oyile yokuthambisa, i-screw cap ye-hub kufuneka isuswe, kwaye isiphelo se-oiling yesixhobo se-oiling kufuneka sicinezelwe ngokubhekiselele kwigxalaba kumjelo weoli.I-torque yokuqinisa iplagi yeoli kufuneka ilawulwe phakathi kwe-157-255 Nm.

Ixesha lokuposa: Apr-05-2023